Tag: boiler water

Improve Plant Efficiency with Waste Heat Recovery

Fabrication, Petrochemical

Sep | 14 | 2017

Improve Plant Efficiency with Waste Heat Recovery In the process industry today, where environmental sustainability is becoming and increasingly important driver in plant decisions, operators need to focus on any means available to reduce energy consumption. In oil and gas refineries, for instance, a great deal of energy is often consumed to heat and cool [...]

Keep reading

3 Design Considerations for Single Phase Process Piping

Fabrication, Oil & Gas, Resources

Sep | 12 | 2017

Process piping plays a critical role in the operation of all process plants. Failure to design and fabricate pipelines correctly can lead to significant production problems and higher costs due to increased pump workloads. In this short blog, we outline three design considerations for single phase pipes, carrying either gas or liquid. 1. Pressure Drop [...]

Keep reading

An Introduction to Two-Phase Separators

Oil & Gas

Aug | 15 | 2017

Two-phase vapor-liquid separators are used in many industries including oil refineries, chemical plants, refrigeration systems, natural gas and petrochemical processing plants. Depending on the specific application and the vapor-liquid mixture being separated, two-phase vessels can be oriented vertically or horizontally. In their simplest form, they are an empty tank that’s used to reduce the velocity [...]

Keep reading

Basic Operation of Three Phase Separators

Oil & Gas

Aug | 15 | 2017

Three phase separators are commonly used in the oil and gas industry for the separation of oil, water and hydrocarbon gases from raw product streams. All crude oils contain dissolved gases that will come out of solution once oil is brought to the surface. The amount of gas in the oil is referred to as [...]

Keep reading

Boiler Refractory and Repair: 101

News

Aug | 15 | 2017

Refractories are heat resistant materials used to line boilers, furnaces and other processing equipment. They play a critical role in reducing heat loss in boilers and maximizing efficiency. The Role of Refractories in Boiler Performance Refractory materials are used to line boiler combustion chambers. High-grade refractories ensure minimal heat loss during the combustion process, thereby [...]

Keep reading

What is Laser Cutting?

Fabrication

Aug | 7 | 2017

Laser cutting is a highly accurate and effective method for cutting mild steel and stainless steel plate. It produces exceptional cut quality and allows for the creation of intricate shapes and small holes. How Does a Laser Cutter Work? A laser beam is a stream of high-intensity light of single wavelength, which is generated by [...]

Keep reading

Boiler Maintenance Tips for Trouble-free Operation

Boiler

Aug | 7 | 2017

Boiler breakdowns can be a costly occurrence in terms of both equipment repair and lost production. Regular boiler maintenance is critical to helping prevent such outages and maximizing boiler efficiency. In this blog, we explore some of the key areas that should be checked to ensure continuous, trouble-free boiler operation. Safety Valves – Safety valves [...]

Keep reading

Column Control for Crude Oil Distillation

Oil & Gas

Aug | 7 | 2017

Effective control of process variables is critical to the production of high-quality petroleum products. In the crude oil refining process, distillation is impacted by two factors; reflux ratio and temperature gradient through the distillation column. Control of Reflux Ratio Reflux is condensed top product that is returned to the upper part of the tower to [...]

Keep reading

4 Factors that Impact Energy Loss in Boilers

Boiler

Jun | 29 | 2017

Boiler efficiency is a measure of the total energy input to a boiler vs. its total energy output. In effect, it is an indication of the energy losses encountered during boiler operation through radiation, convection and inefficient combustion. There are a number of factors that contribute to energy loss and boiler inefficiency. Some of these [...]

Keep reading

4 Common Heat Treatment Methods Used in Fabrication

Fabrication

Jun | 29 | 2017

During metalworking and equipment fabrication, various heat treatment techniques can be used to alter the physical and mechanical properties of materials. Oftentimes, these techniques are used in combination to achieve desired metal characteristics. In this short blog, we discuss four of the most common heat treatment methods during equipment fabrication and material processing: Hardening – [...]

Keep reading

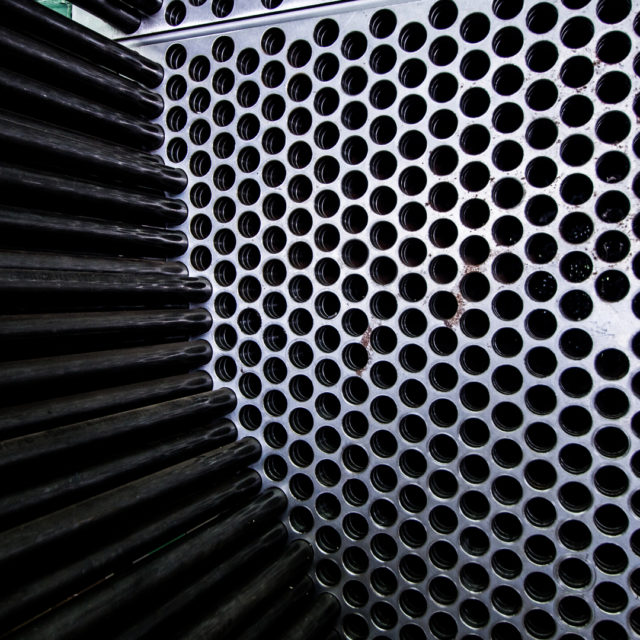

Massecuite Reheater Design and Operation

Sugar

Jun | 29 | 2017

During sugar production, massecuite leaves the crystallizer at approximately 40°C. At this temperature, it is too viscous to separate the sugar crystals from the syrup in the centrifuges and must be reheated to 50 – 56°C. The process must be carefully monitored and controlled in order to minimize the dissolution of crystals and avoid the [...]

Keep reading

5 Design Considerations for Continuous Vertical Crystallizers

Sugar

Jun | 20 | 2017

In sugar processing, poor vertical crystallizer design will often result in channeled massecuite flow and dead spaces within the vessel, leading to a corresponding reduction in crystallization efficiency. Good flow patterns, as well as sufficient retention time and cooling, are essential to achieve adequate crystallization. In this blog, we discuss five aspects of design that [...]

Keep reading

Falling Film Evaporators – 101

Sugar

Jun | 20 | 2017

Falling film evaporators are equipment used extensively in sugar production for concentration of juice. Compared to other types of evaporator technologies they offer a number of operational advantages including increased heating surface area, effective heat transfer over wide temperature ranges, and reduced consumption of steam. Falling Film Evaporator Operation A falling film evaporator is, in [...]

Keep reading

3 Factors Affecting the Operation of Continuous Vacuum Pans

Fabrication, Sugar

Jun | 15 | 2017

Continuous vacuum pans play a critical role in sugar production efficiency and crystal quality. In this short blog, we discuss three important factors that impact their operation. 1) Massecuite Circulation – During evaporation, crystal uniformity is achieved when the flow of massecuite through the vessel approaches plug flow conditions. For this to occur, circulation of [...]

Keep reading

Sugar Processing – Refining Part 3

Sugar

Jun | 8 | 2017

In Part 2 of this blog series we discussed crystallation and drying as it relates to the production of sugar from sugar cane. In this blog, we discuss refining and related sugar processing equipment. Refining Overview Raw cane sugar undergoes several stages in a refining process to produce a range of high quality white and [...]

Keep reading

Sugar Processing -Crystallization and Drying Part 2

Sugar

Jun | 5 | 2017

In this blog, we discuss crystallization and drying in sugar proessing. In Part 1 of this blog series we discussed juice extraction, clarification, and concentration as it relates to the production of sugar from sugar cane. Crystallization The syrup produced in the evaporators proceeds to vacuum pans, where it undergoes further evaporation under vacuum to [...]

Keep reading

Sugar Processing – Juice Extraction, Clarification and Concentration

Sugar

May | 31 | 2017

Juice extraction, clarification, and concentration are critical steps in sugar processing. Below, we discuss what each of these steps entails. Juice Extraction On arrival at the sugar processing plant, sugarcane is loaded onto a conveyor table. It passes through various sugar equipment including a shredder, which uses a series of knives to chop the cane [...]

Keep reading

Honiron Manufacturing: Project Success Series – Non-Destructive Testing (NDT)

Company

May | 31 | 2017

Honiron Manufacturing is an industry-leading provider of inspection and testing services to the sugar, oil and gas, petrochemical and refining, LNG, food processing, and carbon black industries. Over the course of our 160+ years of fabricating and servicing industrial equipment throughout the globe, we’ve continuously strived to develop safer and more efficient manufacturing and inspection [...]

Keep reading

Continuous Distillation Process in Crude Oil Refining

Oil & Gas

May | 29 | 2017

Continuous distillation is a process in which a chemical mixture is continuously fed into a distillation column where its contents are separated through selective boiling. It is used extensively in crude oil refining to produce petroleum products, such as gasoline, lubricants, fuel oil, waxes, and petrochemicals. In this short blog, we outline the steps by [...]

Keep reading

5 Types of CNC Machines Commonly Used in Metalworking

Fabrication, Manufacturing

May | 29 | 2017

Computer Numerical Control (CNC) is widely used for the automation of machines used in metal removal, shaping, and fabrication. There are several types of CNC machines that can be found in fabrication facilities today. Some of these include: CNC Milling Machines - A mill uses rotary cutters to shave, cut or slice sections off of [...]

Keep reading

5 Signs That Your Boiler Needs Servicing

News

May | 23 | 2017

Industrial boilers account for a large portion of monthly energy bills. By being attentive to boiler maintenance needs, operators can reduce costs, improve efficiency, and prolong the life of their equipment. Listed below are five signs that may indicate your boiler needs to be serviced. Water Leaks – Boiler leaks are usually evident by an [...]

Keep reading

Honiron Manufacturing: Project Success Series – Fabrication

Fabrication

May | 23 | 2017

Honiron Manufacturing has been a leading provider of fabrication and welding services since 1852. Over that time period, we’ve developed a deep understanding of what does and doesn’t work when it comes to fabricating high-quality processing equipment and pressure vessels. Here are three best practice guidelines you can follow to ensure project success. 1. Choose [...]

Keep reading

A Look At Sugar Production from Sugar Beets

Sugar

May | 9 | 2017

Unlike sugarcane, which is grown in tropical or sub-tropical climates, sugar beets are grown in temperate regions of North America, Europe and Asia. Beet crops can be stored for several months before being delivered to beet sugar factories. Processing involves several important stages, including: Cleaning and Juice Extraction - Sugar beets are washed to remove [...]

Keep reading

Distillation Columns Used in Crude Oil Refining

Oil & Gas

May | 9 | 2017

A distillation column is a critical piece of equipment in the refining of crude oil. It acts very much like a still, separating product into its different chemical components based on differences in volatility. Oil refineries use two main types of distillation columns. They are: Packed Type Columns – A packed distillation column is a [...]

Keep reading

Oil and Gas Storage Tank Applications and Design Features

News

May | 1 | 2017

Storage tanks are used throughout the oil and gas industry for the bulk containment of fluids at different stages of the refinery process. Most often, products are stored for a short time before being transported for further processing. The American Petroleum Institute’s API 650 standard outlines minimum requirements for the design, fabrication, erection, and inspection [...]

Keep reading

How Combustion Losses Affect Boiler Efficiency

Boiler

Apr | 18 | 2017

Boiler efficiency can be calculated a number of different ways. One method is by taking the amount of heat captured and transferred to the water, and dividing by the total generated heat. If not transferred to the water the heat is considered lost and efficiency is reduced. Types of combustion losses include: Blowdown Heat Losses [...]

Keep reading

Fuel Feed System and Boiler Performance

Boiler

Apr | 18 | 2017

The fuel feed system is a vital performance component of any low-emission boiler. In addition to supplying fuel, a properly designed fuel feed system ensures consistent and reliable combustion by distributing fuel within the boiler. The form and type of fuel also plays an important part in a boiler’s performance and operation. Gaseous fuels, for [...]

Keep reading

Honiron Manufacturing: Project Success Series – Material Procurement

Project Management

Apr | 14 | 2017

Material procurement represents a large portion of the total cost to develop and operate an industrial facility. For over 160 years, Honiron Manufacturing has helped owners and operators maximize the value of their purchases by providing strategic material procurement services to processing facilities around the globe. Over that time period, we’ve developed a deep understanding [...]

Keep reading

Honiron Manufacturing: Project Success Series – Project Management

Project Management

Apr | 14 | 2017

Honiron Manufacturing is an industry-leading provider of project management services to the sugar, oil and gas, petrochemical and refining, LNG, food processing, and carbon black industries. Over the course of our 160+ years of building complex industrial equipment and facilities throughout the globe, we’ve developed a very clear understanding of what does and doesn’t lead [...]

Keep reading

3 Factors to Consider When Choosing an Industrial Boiler

News

Apr | 4 | 2017

Boiler selection plays an important role in maximizing the overall efficiency of an industrial facility. When choosing an industrial boiler, its important to consider the specific requirements of the application it will be used in, as these requirements will dictate 1) the type/design of boiler that is appropriate, 2) the fuel/heat source that should be [...]

Keep reading

Welding Tools Improve Pipeline Surface Preparation

Oil & Gas

Mar | 27 | 2017

Proper surface cleaning and preparation is paramount to ensuring the creation of high quality welds on oil and gas pipelines. Listed below are tips on welding tools to improve those activities and minimize the risk of failure and subsequent damage to both plant and personnel. Use the Right Tools for Surface Preparation Strong, durable welds [...]

Keep reading

An Overview of Boiler Types

Boiler

Mar | 21 | 2017

Choosing the Right Boiler for Your Operation Choosing the right boiler for an operation will ultimately be dictated by the heating requirements of the application and/or process, as well as project-specific factors, such as emissions, efficiency, location, cost, and access to available fuel sources. In every case, ensuring that the boiler has been expertly designed [...]

Keep reading

Understanding Loading on Equipment Skid Packages

Petrochemical

Mar | 20 | 2017

Process skid packages are critical components of industrial facilities whose design and fabrication requires careful consideration of a number of factors in order to operate safely and reliably. Apart from having to accommodate its own weight, a skid package must also be designed to handle the dynamic nature of the equipment on it (compressors, turbines, [...]

Keep reading

Measuring Boiler Efficiency

Industry

Mar | 16 | 2017

Boiler efficiency has a direct impact on overall plant economics. It can be measured in terms of the combustion process or by the transfer of heat to the boiler water. Thermal Efficiency Thermal efficiency is a measure of the heat exchange between the combustion process and the water in the boiler. Expressed as a percentage, [...]

Keep reading

Designing Condensate Piping Systems: 5 Factors to Consider

Oil & Gas

Mar | 9 | 2017

Condensate piping is used to remove condensate from steam-heated vessels, ideally for recovery and re-use in boiler feedwater. When hot condensate under pressure is discharged from a steam trap into a low pressure system, the resultant pressure drop causes some of the condensate to flash into steam. Consequently, the design of condensate piping systems is [...]

Keep reading

4 Benefits of Modular Equipment Fabrication in Oil and Gas

Oil & Gas

Mar | 7 | 2017

Modular construction involves prefabricating equipment and systems into modules offsite in a controlled manufacturing facility. In recent years, the use of modular construction in the oil and gas industry has become increasingly popular because it provides a number of advantages over traditional “stick build” methods of facility development. Some of these include: 1. Shortened Project [...]

Keep reading

ASME Boiler and Pressure Vessel Code (BPVC): A Brief History

Company, Edible Oils, Industry, Oil & Gas, Petrochemical, What We Do

Mar | 1 | 2017

The Boiler and Pressure Vessel Code (or BPVC) is an American Society of Mechanical Engineers (ASME) standard relating to the design, fabrication and inspection of boilers and pressure vessels. The Need for Regulation Following the invention of the steam engine in the 18th century, boilers were put to good use in many industries. However, throughout [...]

Keep reading

An Introduction to Gas Metal Arc Welding (GMAW)

Oil & Gas, Petrochemical, Refining, Sugar

Mar | 1 | 2017

Gas Metal Arc Welding (GMAW) is commonly used for welding alloys, such as stainless steel and aluminum, or any work involving brazing, fabrication or pipework. How GMAW Works The electrode in GMAW consists of a roll of wire that is fed into the work piece by a ‘gun’. The rolled wire electrode allows for the [...]

Keep reading

Manifold Applications in the Oil and Gas Industry

Oil & Gas

Feb | 21 | 2017

Manifolds are used extensively throughout the oil and gas industry for the distribution of gases and fluids. They are designed to converge multiple junctions into a single channel or diverge a single channel into multiple junctions. Simple manifold systems typically are used to divide one supply input to multiple outputs, while more complex systems incorporate [...]

Keep reading

Considerations for Designing Pig Receivers

Company, Industry, Oil & Gas, Resources, What We Do

Feb | 17 | 2017

Pigging is a maintenance procedure used extensively in the oil and gas industry to clean and inspect pipelines carrying refined and unrefined products. The process is made possible by launchers and receivers. Receivers (or traps) are vessels installed on the pipeline that allow for unloading of pigs without interruption of flow. There are a number [...]

Keep reading

Thermal Fatigue Cracking in Pressure Vessels: What You Need to Know

Oil & Gas, Petrochemical, Refining, Sugar

Feb | 13 | 2017

Thermal fatigue cracking is a potentially dangerous condition that occurs as a result of cyclical expansion and contraction caused by temperature variations in industrial process equipment. The extent of damage will depend on the frequency and magnitude of these temperature swings. Damage from thermal fatigue manifests itself in the form of cracking in the equipment [...]

Keep reading

Effective Heat Transfer in Evaporators

Sugar

Feb | 8 | 2017

Juice thickening in sugar plants relies heavily on the heat transfer ability of evaporators. Efficient heat transfer is also fundamental to juice heating and sugar boiling, as well as other sugar production-related processes. Multiple-Effect Evaporators In multiple-effect evaporators, cascade-type heating allows for the utilization of multiple evaporation phases. However, this heating process only succeeds if [...]

Keep reading

The Importance of Venting Non-condensable Gases in Steam Heated Vessels

Sugar

Feb | 8 | 2017

Sugar processing makes extensive use of evaporators for the concentration of raw juice. Evaporation is an energy-intensive operation that uses steam to heat evaporator vessels, called calandrias. There are a number of factors that can impact the efficiency of this process, one of which is non-condensable gas in the steam. Problems Arising from Non-condensable Gases [...]

Keep reading

Shielded Metal Arc Welding 101

Oil & Gas, Refining, Sugar

Feb | 2 | 2017

Shielded Metal Arc Welding (SMAW), or ‘stick welding’ as it’s sometimes called, is one of the most common welding methods used in modern industrial fabrication processes. SMAW involves an electrode, usually a metal rod or stick, clamped to a welding torch to create an electric arc.The high temperature of the arc melts both the electrode [...]

Keep reading

5 Common Non-Destructive Testing (NDT) Techniques

Oil & Gas, Refining

Jan | 31 | 2017

Non-destructive testing (NDT) is widely used for quality control in the fabrication of process plant and equipment. It is a set of techniques used to evaluate the structural integrity of materials and detect any flaws that can compromise their safety or functionality. Here are five of the most common NDT methods in use today. Liquid [...]

Keep reading

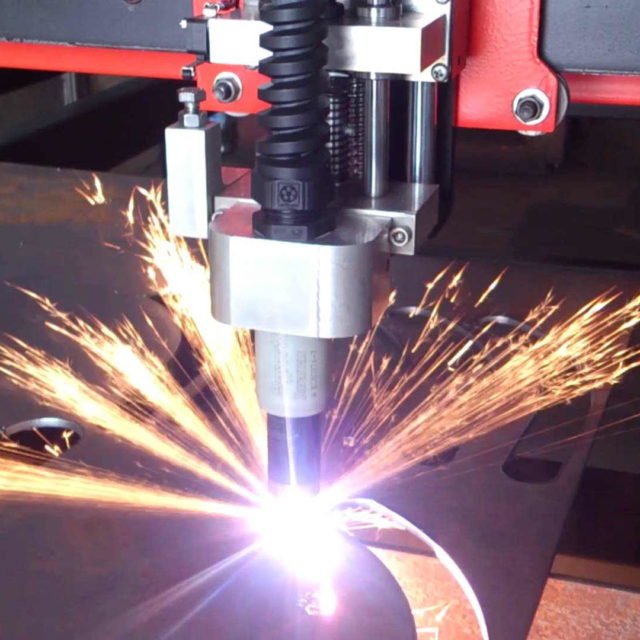

Plasma Cutting: What it is and How it Works

Company, Industry, Manufacturing, Resources, Sugar, What We Do

Jan | 26 | 2017

Plasma cutting (or plasma arc cutting) is a commonly used method for cutting through electrically conductive materials (i.e., metals). It emerged in the 1960s and became popular in the 1980s due to its benefits over metal-to-metal and oxy-fuel cutting. By comparison, plasma cutting produces more accurate cuts with cleaner edges and fewer metal chips. Plasma [...]

Keep reading

Sugar Processing: 101

Sugar

Jan | 25 | 2017

Sugar is produced from two main sources; sugar cane and sugar beet. Sugar cane is grown in warm tropical or sub-tropical regions, whereas sugar beets thrive in more temperate climates. While the choice of processing equipment may vary, the production process is fundamentally the same for both raw materials. It includes the following steps: Cleaning [...]

Keep reading

4 Factors To Consider When Selecting Sugar Processing Equipment

Sugar

Jan | 23 | 2017

The design of a sugar plant is driven by a number of variables that are unique to the location of the facility, as well as the specific objectives of the operator. Careful evaluation of these variables is critical to determining the optimal type and size of equipment to be used in the production process. Here [...]

Keep reading

Boiler System: Reduce Soot Build-Up to Improve Performance and Efficiency

Oil & Gas, Petrochemical, Refining, Sugar

Jan | 19 | 2017

A dirty boiler tube is an inefficient boiler tube. While some degree of soot build-up is inevitable in any boiler system, excessive soot may indicate serious furnace or fuel issues that result in dramatic decreases in efficiency. In firetube boilers, hot gases flow through tubes carrying the byproducts of combustion. Over time, these accumulate to [...]

Keep reading

Choosing the Right Material for your Pressure Vessel

LNG, Oil & Gas, Petrochemical, Refining, Sugar

Jan | 18 | 2017

Improper selection of material is one of the leading causes of failure in pressure vessel. As a result, choosing the appropriate metal for a specific tank application is of the utmost importance. Choosing the wrong material can lead to any number of issues, from poor performance and lower efficiency, to catastrophic failure and reduced safety. [...]

Keep reading

HAVE QUESTIONS? WE CAN HELP.

CONTACT US!